Location:Home > Industry Insights > News & Events

As an annual event in the field of automotive engineering, global headline companies showcased cutting-edge technologies to drive sustainable development in the industry.

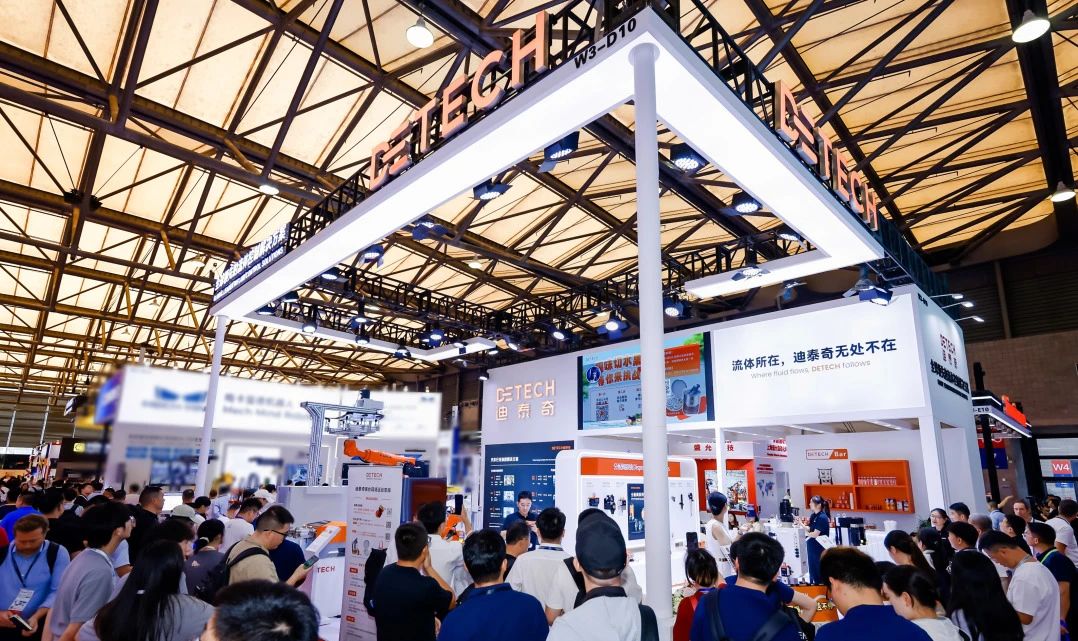

This year's AMTS, DETECH took the theme of “Where Fluid is, DETECH is Everywhere” and brought fluid control products such as fluid conveying, precision metering, closed-loop monitoring and distributing and mixing to the show. The products are widely used in automotive, electronics, new energy and other fields, attracting many customers at home and abroad to stop and exchange ideas.

01

Diversified Products

Feeding - Metering - Dispensing

Automotive glass gluing systems:Stable and precise gluing with high flow rate

- Full-area ±1°C thermostatic control

- ±1% Glue application repeatability

- 99% glue utilization

- 300,000 Liters Trouble-Free Delivery

Metering system: stable glue precision metering

For different glue volume requirements, DETECH has created differentiated metering solutions:

- TID high-performance two-component dual servo metering series: designed for two-component gluing assembly, excellent mixing ratio accuracy, adjustable suction function, support for remote / direct-connected flexible configuration, perfectly adapted to the scene of high filler materials.

- Two-component piston continuous metering Actem 2SC series SVR: set metering, heating, data acquisition, fully automatic control in one, to achieve continuous fluid output, with ultra-high wear-resistant sealing structure, long service life, low maintenance costs.

Dispensing Valve Series: Precision Mixing Centralized Debut

Two-component PU high-pressure collision mixing valve: Relying on the super 200bar high-pressure jet technology, it realizes the millisecond high-speed collision of A/B components, completely breaking the laminar flow state, and the mixing uniformity is as high as 99%.

Two-component dynamic stirring mixing valve: adopts multi-stage mixing core structure, high-speed rotation to help glue fully mixed, goodbye to the inefficiency and unevenness of the traditional stirring and mixing.

In addition, DETECH also displayed a number of innovative products such as two-component pneumatic switching valves, one-component rotary glue applicator valves, grease injection valves, etc., which help the industry to synchronize the leap in efficiency and quality with precision technology.

02

On-site multi-dimensional sensory experience

On the exhibition site, DETECH not only has abundant exhibits, but also has three innovative experience zones: the explanation zone, the fun game interaction zone and the exclusive beverage zone, building a sensory interactive space, so that the audience can be deeply immersed in the process of strolling through the exhibition.

03

Multi-scene application, multi-process coverage

The products and solutions brought by DETECH are related to the gluing process in the automobile production process, welding, painting and assembly workshop. Dytachem provides systematic solutions for sealing, bonding, potting, foaming and spraying, helping automobile production to a new height.