Location:Home > Industry Insights > Industry Solutions > Motor Vehicles

Vacuum potting technology ensures that the potting material can completely penetrate into every small gap inside the component by potting in a vacuum environment, forming a high-quality potting layer with no bubbles and no voids.

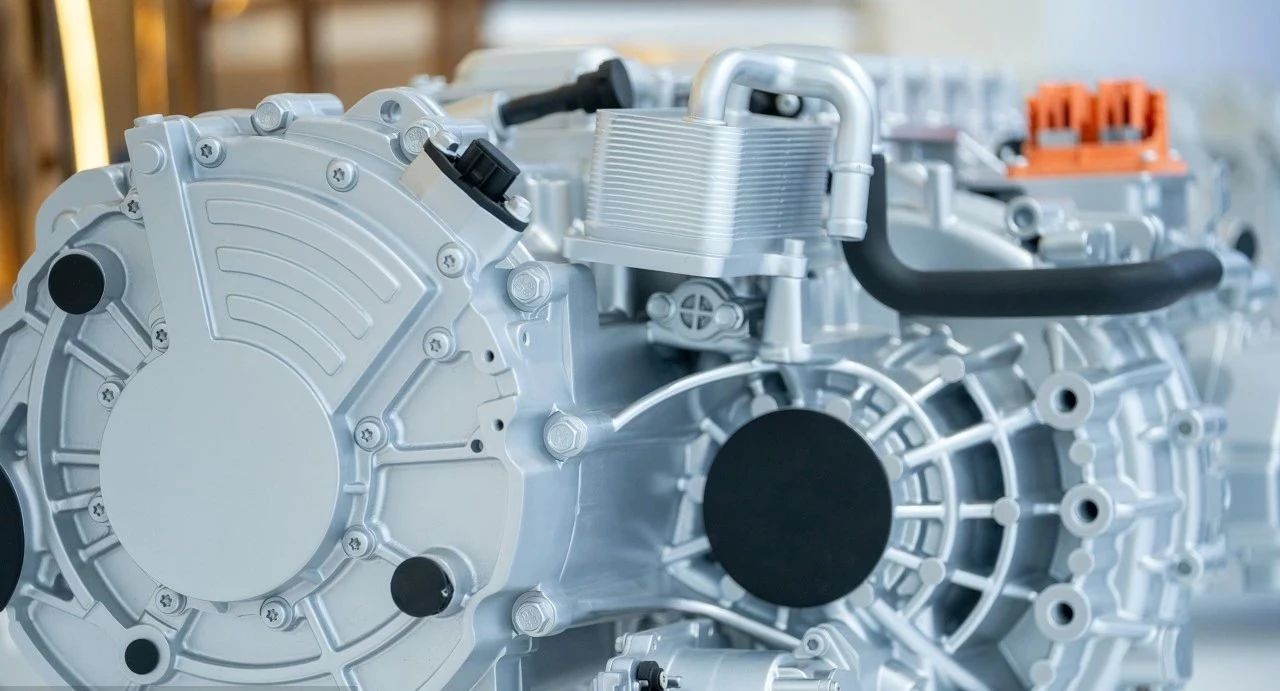

In the production workshop of a well-known automotive parts company, the air valve potting process is facing a severe test. Under the double pressure of efficiency and quality, the customer approached DETECH team, hoping to provide a set of solutions to help them solve a series of challenges in the air valve potting production process.

1. Efficiency bottleneck: the production line requires a single piece of production beat compressed to 29 seconds, but the existing equipment due to low glue mixing efficiency, poor glue stability, low efficiency of multi-process convergence, seriously slowing down the rhythm of the production line, and become a bottleneck to improve production capacity.

2. Accuracy and consistency of the problem: the glue speed needs to be stabilized at 3.3cc / s, the amount of glue error ≤ ± 3%, and the volatility of the traditional gluing equipment, resulting in a potting qualified rate of less than 85%.

3. Glue mixing and air bubbles: A/B component glue needs to be accurately proportioned, uneven mixing will easily produce air bubbles, affecting the reliability of potting. Customer feedback, air bubble residue leads to the air valve pressure test failed, customer complaints frequently.

4. Automation upgrading cost pressure: the equipment needs to be compatible with the customer's multi-model products, and the requirements of long-term stable operation, the traditional transformation program of high cost and long cycle.

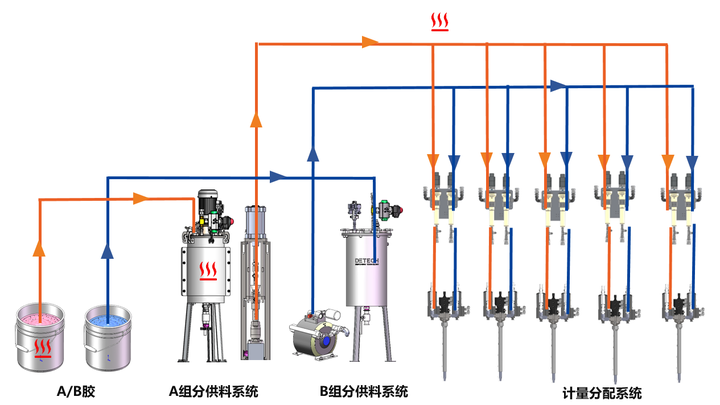

Feeding + Transit + Metering + Distribution

● Vacuum pump feeding: adopting vacuum pump for feeding, high vacuum efficiency; air-cooled structure, no need for external water-cooling box, reducing system maintenance costs.

● T60 Transfer Tank: T60 transfer tank is adopted, equipped with vacuum defoaming, liquid level detection, stirring, heating and nitrogen protection functions to ensure that the processed glue is pure and bubble-free, and the filler is evenly distributed. It is equipped with plunger pump and diaphragm pump to pump the material and transport the glue to the metering system.

● Screw Valve Metering: Adopting screw valve for metering, servo-driven, continuous and uninterrupted gluing, adapting to the requirements of fast beat production, with flow and pressure monitoring system, high gluing precision.

● PDT3 dispensing valve: Adopting PDT3 dispensing valve, the outlet with static mixing tube realizes two-component glue mixing. With full servo-driven three-axis actuator, the trajectory is adjustable and high precision, realizing all-round and dead-angle free filling.

FACE Vacu 120Tr Vacuum Potting Machine

Specialized in the design and development of solutions for the sealing of electronic and electronic control products, the product performance is stable and reliable, easy to use and efficient, compact and intelligent.

● Off-line, in-line equipment available.

● Flexible vacuum adjustment for beat improvement.

● One-piece main cabinet design.

DETECH Automates Gluing Solutions with Full-Link Automation

Helping customers realize the double breakthrough of “efficiency leap + quality enhancement”

﹀

﹀

﹀

Customers realize both efficiency and quality improvements

● Production efficiency: 3.3cc/s gluing speed precision control, single piece of pure gluing time compressed to 20s;

● Quality Enhancement: Achieve bubble-free, void-free, stable and consistent high-quality potting, and near-zero fault stable operation performance;

● Cost reduction and efficiency: modular design reduces maintenance costs; professional after-sales team support, significantly reducing maintenance workload.

DETECH always focuses on the core challenges of automated gluing and drives technological innovation with customer needs. If you are also facing the challenges of efficiency and precision in the gluing process, please contact us to customize your own solution!