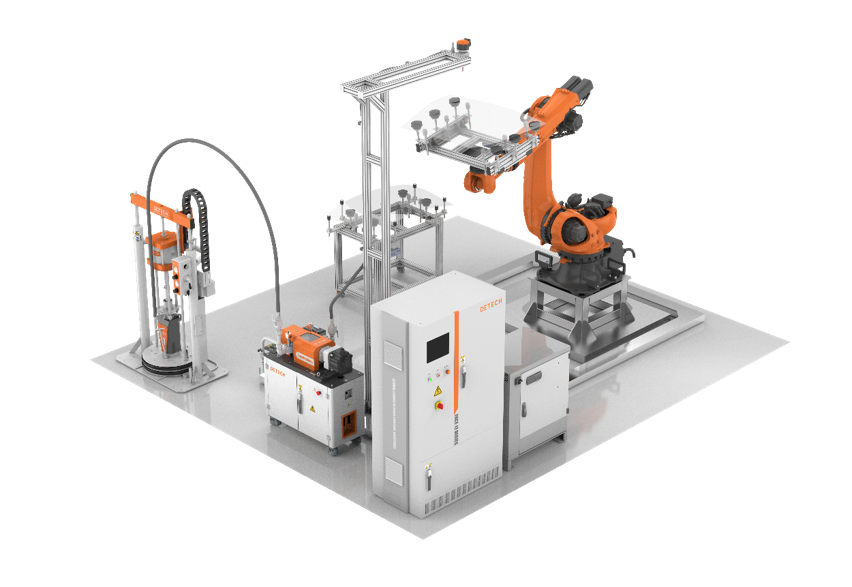

Location:Home > FACE Glass 120Automotive Glass Gluing System

The glass coating system is divided into four modules: feeding, metering, distribution, and six axis robot. The DC Warm series pressure plate pump can handle special processes that require heating (up to 70 ℃). The high-pressure gear pump adopts precision servo control, high flow metering, and is designed specifically for glass coating applications. The rotary glue gun is designed specifically for glue application scenarios that require special cross-sectional shapes and sizes. It can reduce the number of robot axes, simplify the dispensing process, and lower client costs. This module is easy to install and is widely used in the automotive parts industry.

High flow rate feeding & high flow rate continuous glue discharging precise metering.

Multi-zone heating with precise temperature control.

Precision servo motor and high repeatability gear pump.

Lightweight, high-flow, high-pressure gluing valve built for automated gluing applications.

Rotatable glue valve, not limited by cables and hoses.

Data Download

Data Download

+86 0512-68701786

+86 134-0267-9485