Location:Home > Industry Insights > News & Events

On December 12, the Technical Exchange Conference on Forming and Welding of New Energy Vehicle Structural Parts, co-hosted by the Ningbo New Energy Vehicle Research Association and the Ningbo Foundry Industry Association, was successfully held at Xusheng Group. As a world-leading supplier of fluid control solutions, DETECH made a brilliant debut with a themed presentation entitled Application of Foam Adhesive and Potting Adhesive Technologies in New Energy Structural Parts, and garnered extensive attention on-site for its highly targeted and technologically innovative content.

DETECH's Path to Breakthroughs in Foaming and Potting Processes

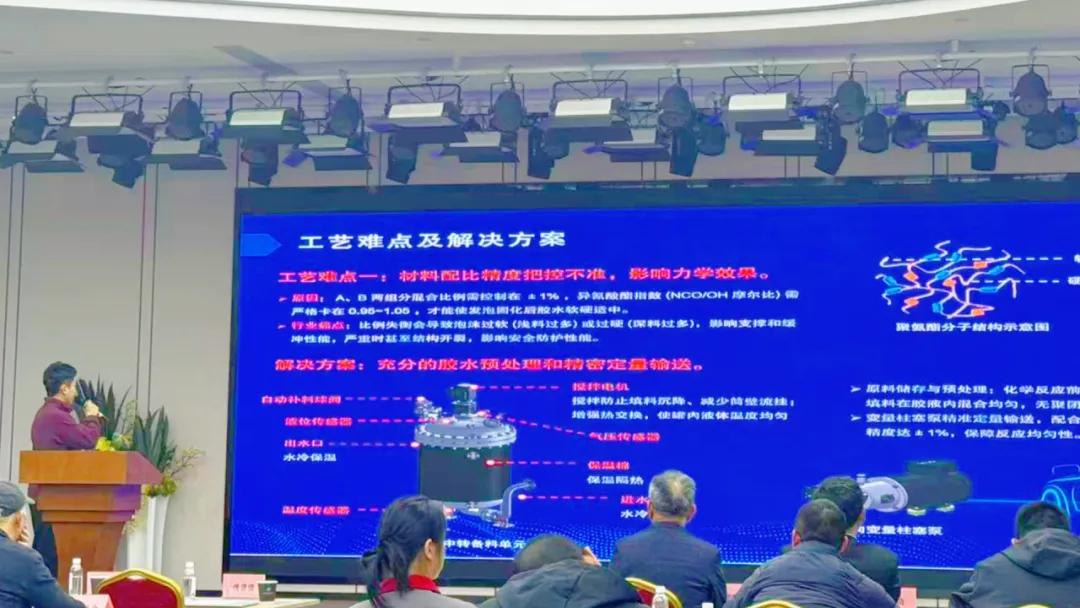

During the presentation session, DETECH analyzed the large-scale application and trends of foam adhesives and potting adhesives in new energy vehicle production. However, pain points in actual production such as insufficient mixing uniformity, unstable reaction rates, and residual bubbles affecting sealing performance have restricted production efficiency and product quality stability.

Combining practical application cases, DETECH systematically disassembled the core points of process implementation from material handling to equipment optimization, and delivered targeted full-process solutions, providing new ideas for enterprises to break through production bottlenecks.

Innovative Equipment, Elevate Process and Production Standards

On-site, DETECH simultaneously showcased the country’s first two-component polyurethane high-pressure foaming equipment — the FACE Foam 125HD special machine for two-component polyurethane high-pressure foaming, as well as the FACE Vacu 120Tr special machine for vacuum potting.

The FACE Foam 125HD adopts flowmeter closed-loop control, with the glue output and mixing ratio accuracy reaching ±1%. It achieves constant temperature control through internal water circulation, and can conduct all-round monitoring of multiple parameters such as pressure, temperature and flow rate. The special machine enables full atomization and mixing of raw materials, with a utilization rate of over 90%, and features short foaming time and fast molding speed.

The FACE Vacu 120Tr is a high-efficiency and intelligent potting equipment designed for the sealing requirements of electronic and electric control products, supporting both online and offline operation modes. Equipped with the DECS control system and integrated with a one-piece main cabinet design, the equipment features a compact structure and convenient operation, delivering stable and reliable performance, as well as user-friendly and high-efficiency application. It enables stable potting of both single-component and two-component materials.

In the future, DETECH will continue to deepen its investment in technological R&D, strengthen collaborative cooperation with industrial chain partners, and empower the upgrading of the new energy vehicle industry with higher-quality products and services.