Location:Home > Industry Insights > Industry Solutions > New Energy

During the lightweighting process, effectively bonding parts with different substrates has become a challenge, highlighting the importance of automotive adhesives. Especially in the field of new energy vehicles, with the advancement of power battery technology, the requirements of adhesive application technology are also improving.

The FACE 12 series is the adhesive applicator for battery side panels.

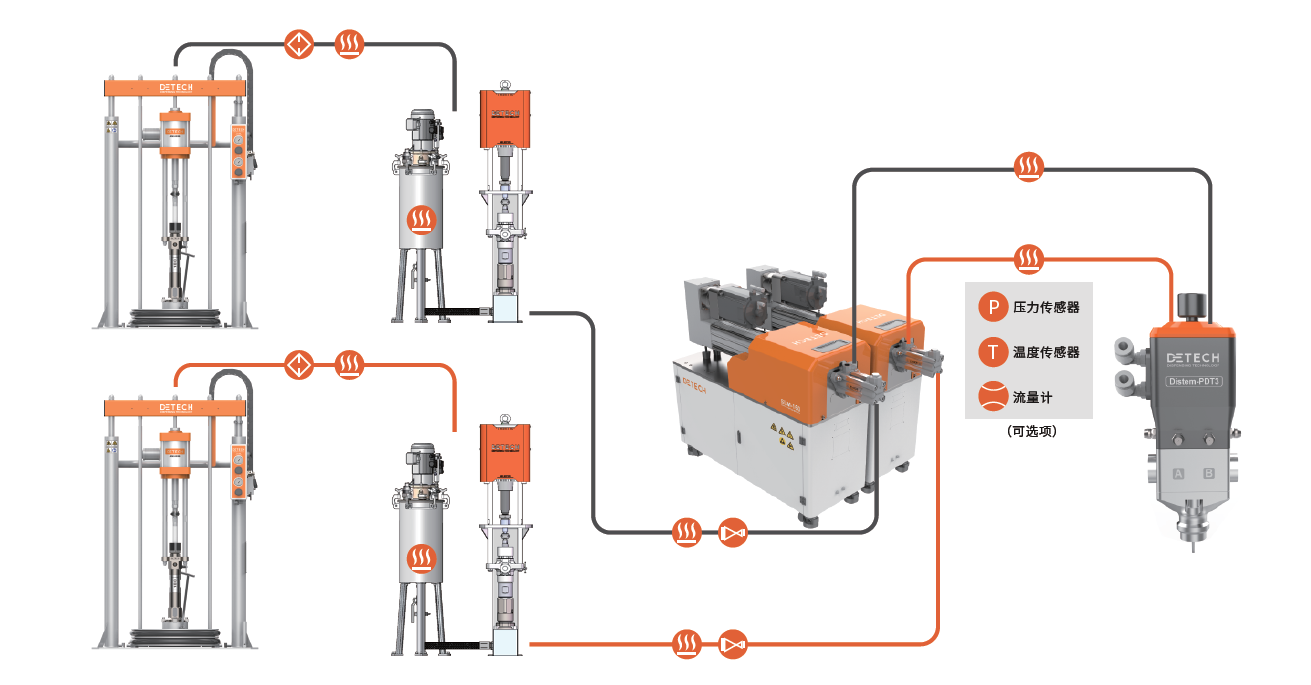

The FACE 12 series coating platform is designed for the battery side panel of a foreign electric vehicle, perfectly adapted to the coating needs of complex materials such as high filler thermally conductive adhesives. The successful application of this platform is due to the high degree of synergy and innovative design of its core components. Whether it is the stability of material supply, the accuracy of metering, or the durability of the dispensing valve, the FACE 12 series has demonstrated excellent performance, providing a reliable guarantee for the bonding of battery side panels.

The DC05/55 Damd series adopts an ultra-wear-resistant plunger design, which is particularly good at handling highly packed heat-conducting adhesives. The system supports flexible customization of drive mode, column structure, plunger pump volume and pump body material to meet diversified production needs. Anti runaway function: effectively improve operation safety. Intelligent operation interface: Users can monitor the life of spare parts in real time and carry out maintenance in advance to ensure stable operation of the system for a long time. High-load piston pump: the volume covers 60cc to 1200cc, adapting to different flow requirements. Long-life seal structure: super wear-resistant ceramic material, single coating material life up to 250,000 liters significantly reduces spare parts loss.

The Actem 2SC-DLM two-component continuous metering system combines metering, monitoring, thermoregulation, data acquisition and fully automatic control. The high thrust design easily handles a wide range of flow rates, the ultra-high outgassing accuracy ensures product consistency, and the wear-resistant ceramic material reduces maintenance costs by more than 50 percent.

This system is particularly suitable for high filler, high thermal conductivity fluids and is compatible with a wide range of two-component adhesives such as epoxy, silicone and acrylic.

Suction back scored design for easy adjustment;

Oil reservoir lubricates valve stem for extended life;

High-load piston pump: Volume covers 60cc to 1200cc, adapting to different flow requirements.

Long-life sealing structure: ultra-wear-resistant ceramic material, single coating material life of up to 250,000 liters significantly reduces spare parts loss.

The FACE 12 Series gluing platform offers a proprietary solution for electric vehicle battery side panels with its high-precision feeding, continuous metering and reliable dispensing capabilities.

Whether it is the stability of product quality or the improvement of production efficiency, the FACE 12 series has won the trust of customers with its excellent performance and helped the manufacturing of new energy automobile batteries to move towards a new height of intelligence.