Location:Home > Industry Insights > Industry Solutions > New Energy

Thermally conductive adhesive contains more than 60% of metal oxides, hydroxides and other high hardness filler particles, with abrasive, easy to delamination, easy to block the characteristics of the flow channel, and the wear resistance of the pumping equipment and metering system for long-term accurate measurement of a very high challenge.

A well-known domestic supplier of power batteries for new energy vehicles. The company occupies an important position in the new energy vehicle market by virtue of its strong technical strength and market influence. Its battery products have won wide recognition from customers for their excellent performance and reliable quality.

They approached the DETECH team to provide a solution to help them address a number of challenges in the coating of thermally conductive materials as well as other production processes:

1. often face downtime, maintenance: the current use of equipment coated with two-component thermally conductive materials, and materials are often in a high-pressure environment to block the fluid flow path and regulator, often face downtime, maintenance.

2. Filler clogging: due to the large flow of glue, the system is prone to generate high pressure, resulting in glue patter, resulting in filler material on the system components of the clogging, affecting the normal application of glue.

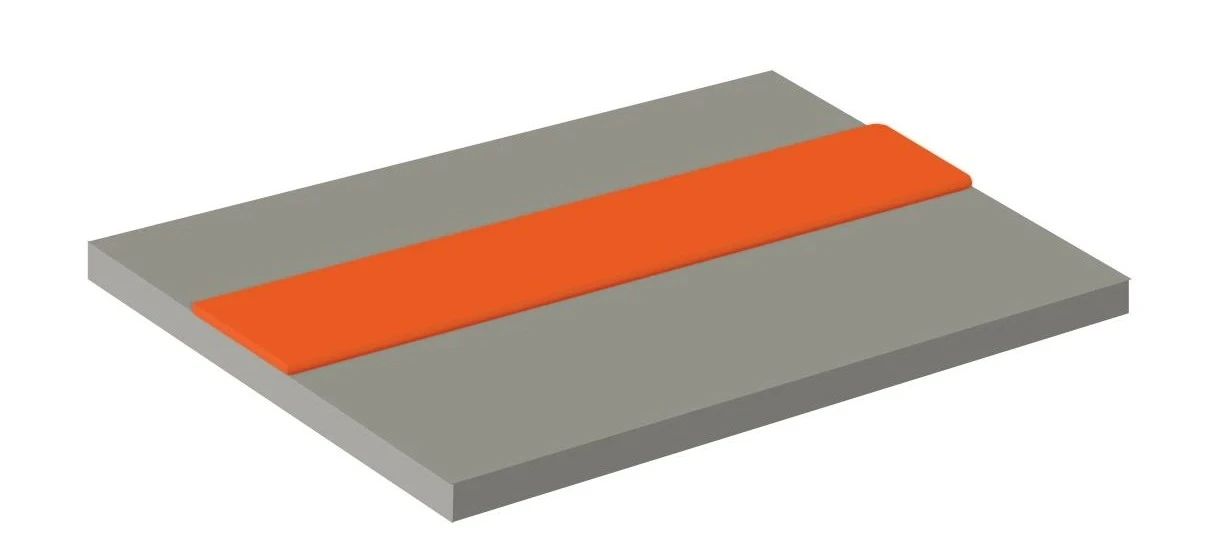

3. Poor process stability: to ensure that the thermal conductive adhesive in the entire contact surface of the uniform distribution is to ensure good heat conduction of the key. The current equipment coating line width fluctuations, affecting the uniformity of heat conduction.

4. Production efficiency bottleneck: the current gluing speed can not match the modern production line beat, the need to speed up the production beat (to achieve more than 45cc / sec flow).

With many years of experience in thermal conductive adhesive coating, DETECH communicated with the customer's technical engineers, conducted tests, and gained an in-depth understanding of the materials used by the customer, the current state of the equipment, the needs and pain points of the application, and ultimately chose the DETECH FACE 12 series of adhesive coating platforms, which is perfectly adapted to meet the needs of the application of high-fillers in the thermal conductive adhesive.

DC 55 Damd Double Column Super Wear Plunger Platen Pumps

● Super wear-resistant technology: the cylinder and plunger rod are made of super wear-resistant ceramic material, and the life of single coating material is up to 250,000 liters, which significantly reduces the loss of spare parts and maintenance costs;

● Intelligent operation interface: Users can monitor the life of spare parts in real time and carry out maintenance in advance to ensure stable operation of the system for a long time;

● Anti runaway function: effectively enhances operational safety;

● Flexible customization: The system supports flexible customization of drive mode, column structure, plunger pump volume and pump body material to meet diversified production needs.

T60+ PM Damd degassing transit system

● T60 transit tank with super wear-resistant pump, the filler particles in the glue will be fully stirred to reduce the rate of oil sleet;

● The T60 transit tank is equipped with an infrared-sensitive lighted sight glass;

● The T60 transit tank allows for speed monitoring, temperature monitoring, and high and low level monitoring.

Actem 2SC-DLM Dual Servo Variable Ratio Ultra Precision Metrology System

The Actem 2SC-DLM two-component continuous metering system combines metering, monitoring, thermostat, data acquisition and fully automatic control. Ultra-high outgassing accuracy ensures product consistency, especially for high filler, high thermal conductivity fluids, and compatibility with a wide range of two-component adhesives such as epoxy, silicone, and acrylic.

● Wear-resistant ceramic materials reduce maintenance costs by more than 50 percent, and reservoir lubrication extends the life of the valve stem and significantly reduces spare parts losses;

● The high thrust design easily handles a wide range of flow requirements, 960-4800 cc/min;

● Suction back scored design for easy adjustment.

Distem PDT6 two-component high flow switching valve

● Highly wear-resistant fluid contact parts for long service life;

● High-flow continuous dispensing, optimized gluing path design to fit the shape of the bottom of the PACK box for gluing.

With the DETECH FACE 12 series of gluing platforms, the automotive power cell plant quickly received an increase in assembly line performance:

● Significantly reduces material clogging with virtually no clogging repairs;

● Flow rate up to 45cc /s to meet the production beat;

● High-quality adhesive strips with no snake heads or tails reduce rework.